ASKUBAL Bearings is a renowned manufacturer specializing in high-quality rod ends and spherical plain bearings designed for precision and reliability. With a strong reputation for excellence, ASKUBAL Bearings serves a wide range of industries, including automotive, aerospace, manufacturing, and heavy machinery. Their innovative designs and durable materials ensure optimal performance, even under demanding conditions. Committed to engineering excellence and customer satisfaction, ASKUBAL Bearings provides tailored solutions that enhance operational efficiency and meet the highest industry standards.

Rod ends

Rod ends are ready-to-install spherical bearing units. In some places they are also called ball joints. They consist of the rod end housing with threaded shaft and the mounted or pressed-in spherical plain bearing. Rod ends are available with a female thread, that means the threaded shaft has a hole into which the thread is cut, or with a male thread, in which case the thread is on the outside of the threaded shaft. Depending on the direction of rotation of the thread, it is a right-hand thread or a left-hand thread.

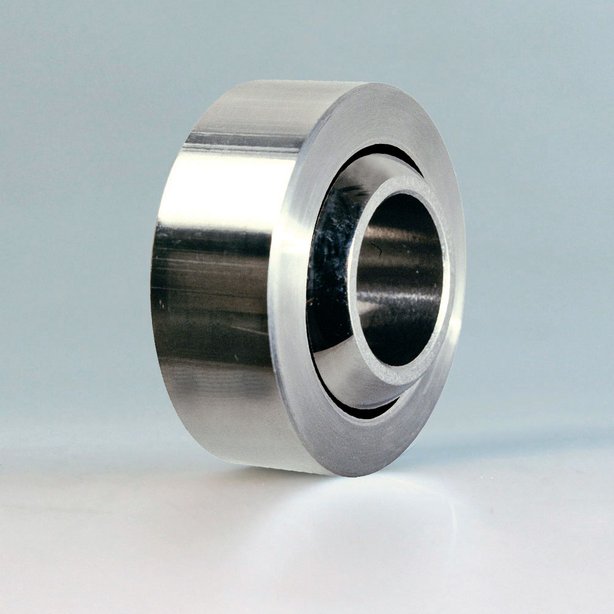

Spherical Plain Bearings

Spherical plain bearings are ready-to-install bearing elements. They consist of a spherical inner ring and an outer ring that can move against each other. They ensure spatial adjustment movements between shaft and housing; enable swivel movements, tilting movements up to a certain tilt angle and orbital movements at relatively low sliding speeds and compensate for misalignments. In combination with a housing, a ready-to-install unit is created which is called a rod end.

Motorsport

Our motorsport rod ends and spherical plain bearings are available in different series, in metric dimensions or in inch dimensions, dimensional series K or E, maintenance-free with PTFE sliding film, maintenance-required, with V-groove or without, for rod ends as internal or external thread, right-hand, left-hand or fine thread. The bearing clearance is always reduced for motor sport bearings. We develop special designs or customised bearings based on your requirements.

Ball and Roller Bearings

A rolling bearing consists of an outer ring, the rolling elements, a cage for the rolling elements and an inner ring. Due to the shape of the rolling elements, the contact area to the raceways is very small. This results in large loads on the smallest surfaces, which in turn requires the best materials and the highest precision in the manufacture of the rolling bearings. The materials used for this purpose must have hard surfaces such as rolling bearing steel (100Cr6), stainless steel (AISI 440C) or even ceramic materials.

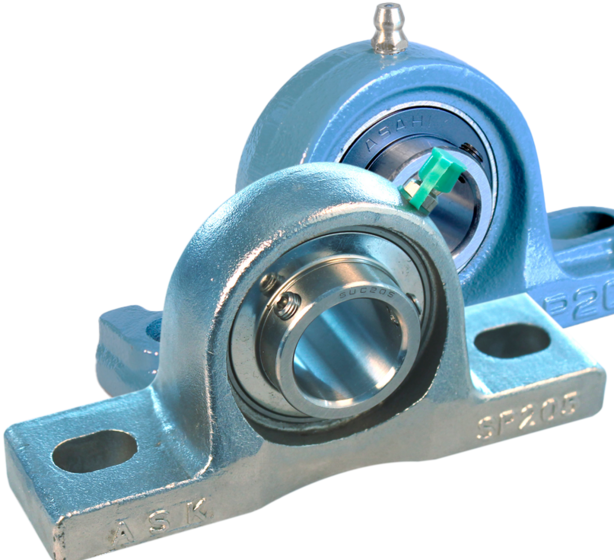

Bearing units

Bearing units are essential components in machinery, combining a bearing and a housing into a single unit for easy installation and maintenance. They are designed to support shafts, accommodate misalignment, and handle both radial and axial loads. Bearing units come in various styles, including pillow block, flange, and take-up units, making them versatile for a wide range of applications. With features like sealed bearings and durable housings, they ensure reliable performance, reduce downtime, and simplify equipment design in industries like manufacturing, agriculture, and automotive.

Cam Followers

Track rollers, rollers followers and cam followers have a thick-walled outer ring and belong to the group of rolling bearings. They can be used with or without an inner ring. Single row track rollers are designed like deep groove ball bearings and double row track rollers like angular contact ball bearings. Roller followers are compact, highly rigid bearings that can support significantly higher radial loads than track rollers. Cam followers are roller followers with a solid pin (roller stud) which helps them to be mounted in a simple and compact manner. In contrast to ball bearings, no balls are used as rolling elements here, but rollers or needles.

Clevises and Bolts

A clevis is an element used for static force transmission. Clevises are used as connecting elements for simple linear movements such as pushing and pulling.

Clevises are usually manufactured in accordance with DIN 71752. DIN 71752 specifies the dimensions, designations and tolerances of clevises / fork elements.

Shaft Hub-Connections

Shaft-hub connections play an important role in drive technology. They are the connecting element between the shaft and the machine elements mounted on the shaft, such as a gear or pulley. The main function is to transmit torque and power. Shaft-hub connections are divided into three groups: positive-locking, friction-locking, material-locking shaft-hub connections and combinations thereof.

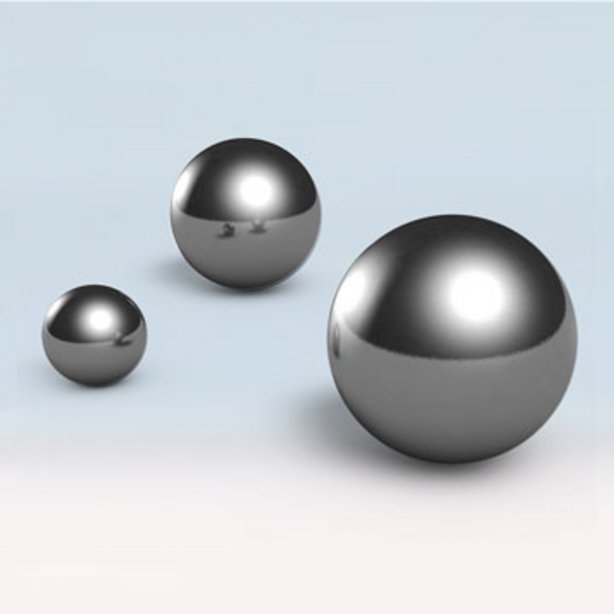

Steel Balls

Balls have been used for decades for a wide variety of applications. Especially the use of steel balls, stainless steel balls and carbon steel balls has been indispensable since the beginning of industrial production. To ensure the comparability, uniformity and quality of steel balls, they are manufactured according to the DIN 5401 standard, which provides information on grades, degrees, hardness and materials.